Publication date: 2025-05-01

Which Plastics Are Truly Worth Recovering—from the Perspective of Practice, Market, and Science?

Not everything can be processed.

Not everything is worth recycling.

Yet, something must be done with it.

From years of working in plastics processing—mainly LDPE and HDPE—I observe that the concept of "recyclability" is often stretched to the point of absurdity. The technical possibility of processing does not necessarily mean economic viability or actual material return to the cycle.

At Uniplast, we have long implemented internal recycling and use only certified LDPE and HDPE regranulate from trusted sources. However, observing the market, I believe it's worth asking: which plastics make sense in recycling today, and which do not?

What Does "Recyclable Plastic" Really Mean?

According to ISO 18604:2013, recycling means material or chemical recovery—but that's just theory. In practice, it depends on:

• Chemical composition (is it a homogeneous polymer?),

• Waste purity (is it clean, uncolored?),

• Source (industrial vs. municipal),

• Market availability for regranulate.

According to the EEA report (2023), only about 40% of plastics declared as recyclable actually return to circulation in the EU. The rest ends up in RDF or landfills.

Plastics That Are Truly Worth Recovering

In our practice, as a manufacturer of LDPE and HDPE plastic bags, the key factors are purity and homogeneity of the raw material. These determine process stability and the quality of the final product.

Recyclers—such as Stena Recycling or Plastics Recyclers Europe—concur. Here are materials with real value:

• PET from bottles – easy to sort, stable demand,

• Industrial HDPE – clean, white, natural,

• Industrial and agricultural LDPE (after washing) – e.g., construction films, transport films,

• PVC from demolitions – profiles, pipes,

• EPS from industrial packaging – compact, clean, without prints.

LDPE (branched) yields more flexible films, HDPE (linear) – rigid bags and packaging. Both types require different processing conditions and regranulate quality.

Plastics That "Can Be" but Are Not Worth It

Despite declarations, many plastics end up in RDF. Why? Because:

• They are too contaminated (e.g., food packaging, sachets),

• They are hard to sort (e.g., black plastics, polymer mixes),

• There is no market for them (e.g., PS, colored HDPE).

Colored HDPE—although technically the same polymer—has lower value because its regranulate yields a grayish, hard-to-use material. Black doesn't pass through NIR sorters.

And If Recovery Isn't Possible? Is Pyrolysis the Way?

Here comes an alternative: chemical recovery (mainly pyrolysis), i.e., the breakdown of plastics in anaerobic conditions. Studies (e.g., Journal of Cleaner Production, 2021) show that:

• Pyrolysis can recover up to 70–80% of the energy value of plastics,

• It can be effective for PE/PP mixes, films difficult in mechanical recycling,

• However, it requires clean input and high CAPEX investment.

Although the technology has potential, its implementation in Poland is limited by lengthy environmental procedures and lack of clear legal support.

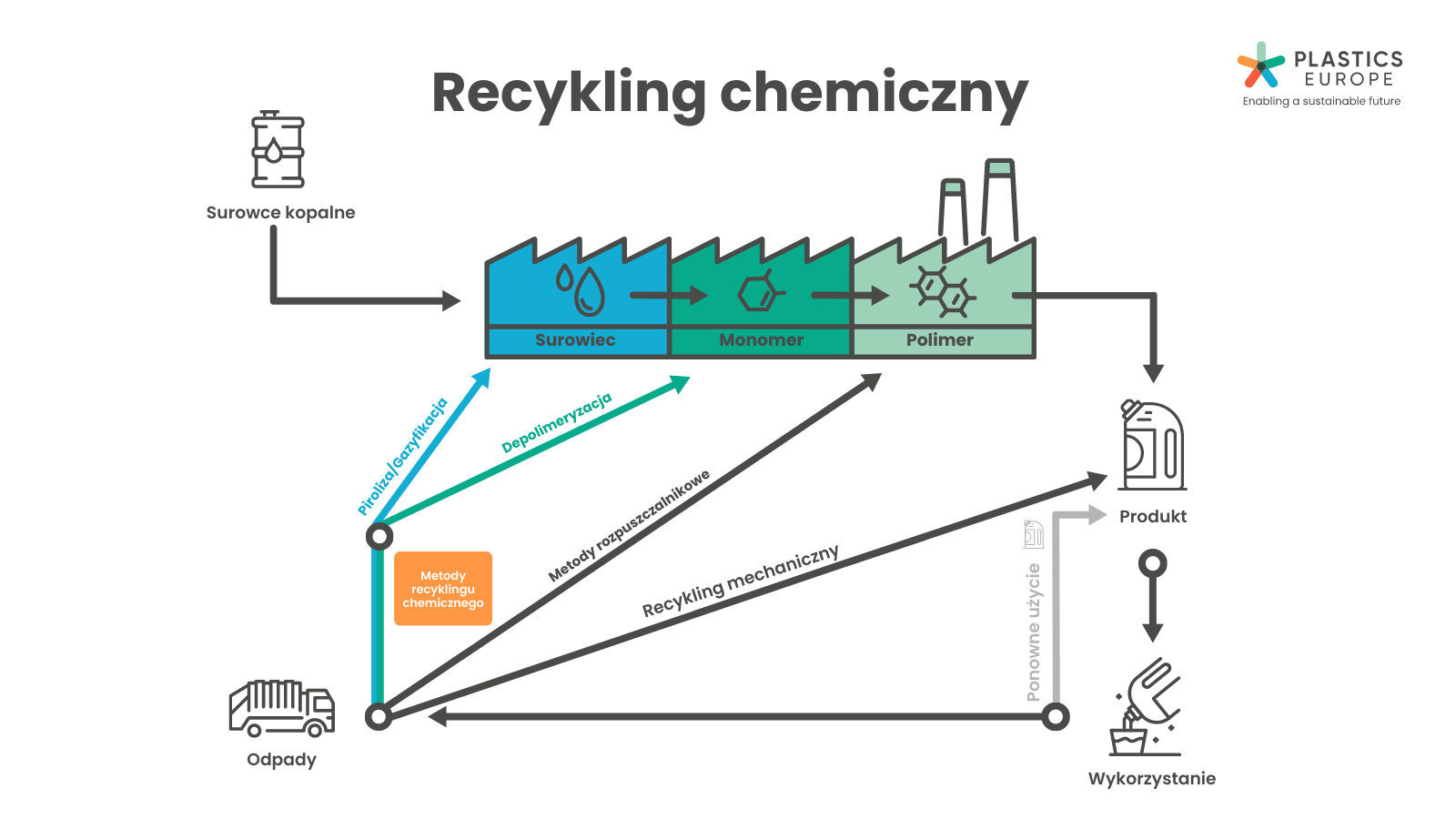

Mechanical vs. Chemical Recycling

Comparison of two recovery paths

Source: Plastics Europe

Mechanical recycling works for clean, homogeneous waste. Chemical—for the rest. But not every system can (yet) implement it.

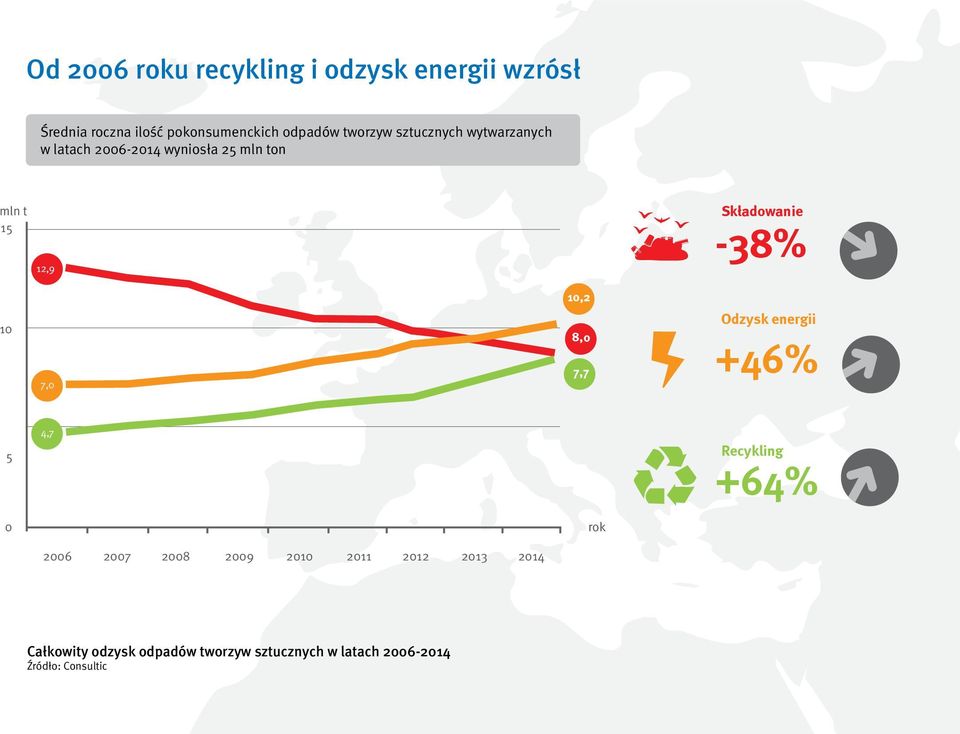

Plastic Consumption and Production – European Context

Plastic production in Europe (2023)

Source: Plastics Europe

The European plastics industry is mainly based on PE, PP, and PET. Therefore, their recycling should be the foundation of the circular economy.

Conclusions – Practical and Technical:

• Recycling is not an idea but an industrial process,

• What pays off is clean, homogeneous, and market-demanded,

• HDPE and LDPE have value—but only from reliable sources and without contaminants,

• Chemical recycling is the future for difficult plastics—but not for every plant,

• At Uniplast, we focus on what can realistically be closed in the loop—without illusions and without wasting raw material.

References

1. European Environment Agency, Plastics waste trade and the circular economy, 2023.

2. Joint Research Centre, Assessment of plastic recycling systems, 2022.

3. Plastics Recyclers Europe, State of the European plastics recycling market 2023.

4. Stena Recycling, Circular Material Flows Report, 2023.

5. Plastic waste to value via pyrolysis – A review, Journal of Cleaner Production, 2021.

6. PlasticsEurope, Plastics – The Facts 2023.

7. ISO 18604:2013 – Packaging and the environment – Material recycling.

Keywords (SEO):

#Uniplast #LDPEFilm #HDPEFilm #LDPEBags #HDPEBags

#PlasticRecycling #CircularEconomy #Pyrolysis

#RegranulateLDPE #RegranulateHDPE #PlasticBagManufacturer #PlasticsIndustry