Publication date: 2025-05-15

HDPE and LDPE Bags – Practical Guide to Differences and Applications

HDPE and LDPE plastic bags are widely used in everyday life — from food packaging to industrial waste. Although both materials are types of polyethylene, differences in their structure and properties mean they are suitable for very different applications.

In this article, we explain:

- the main differences between HDPE and LDPE,

- when to use each type of bag,

- what to consider when choosing the right material.

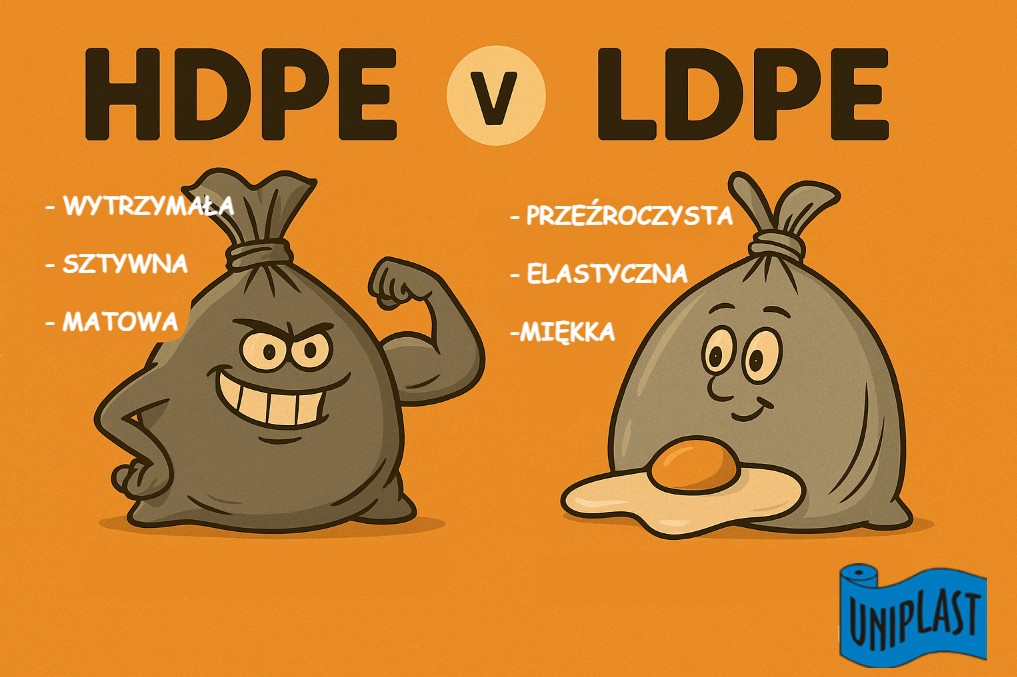

HDPE vs LDPE – What’s the Difference?

The primary difference lies in density and internal structure:

| Property | HDPE (High-Density Polyethylene) | LDPE (Low-Density Polyethylene) |

| Density | High (0.94–0.97 g/cm³) | Low (0.91–0.94 g/cm³) |

| Structure | Rigid, less flexible | Soft, flexible |

| Strength | Very good mechanical resistance | High stretchability |

| Appearance | Matte, milky surface | Transparent or semi-transparent |

HDPE is harder and more resistant to puncture but less elastic. LDPE, on the other hand, stretches and adapts to the shape of its contents.

Applications in Practice

HDPE is used where tear resistance and durability are key at a low unit cost:

- municipal and industrial waste bags,

- shopping bags,

- technical packaging.

LDPE is chosen for applications requiring flexibility and aesthetic appeal:

- food bags (bread, vegetables, frozen products),

- protective films,

- bulk packaging for lightweight items.

Choosing Plastic Bags – What Matters?

Choosing between HDPE and LDPE is not just about price. Important factors include:

- the type of product to be packed (weight, shape, sharp edges),

- storage conditions (humidity, temperature),

- required aesthetics (transparency, printability),

- ecological aspects (recycled content, film thickness).

Producers often adjust film parameters (thickness, width, type of recycled material) to match customer needs, optimizing functionality and material consumption.

Plastic Bags and Ecology – A Contradiction?

While plastic is often criticized, modern packaging production has evolved significantly:

- increasing use of recycled materials,

- thinner yet durable films,

- minimization of production waste,

- clear labelling of recycled content on products.

Choosing responsible suppliers can significantly reduce environmental impact.

Summary

- HDPE and LDPE differ in structure, strength, and application.

- Material choice depends on product function, economic, and environmental factors.

- Manufacturers offer tailored solutions, both from virgin and recycled materials.

- An informed choice balances cost, quality, functionality, and responsibility.

#PlasticBagManufacturer #HDPEBagsProducer #LDPEBagsProducer #PrintedPlasticBags #RecycledPlasticBags #HDPELDPEFilm #TrashBagsProducer #MedicalWasteBags #FoodGradePlasticBags #PlasticSleeveFilm #PlasticPackagingManufacturer #UniplastFolia