Recycled Plastic Bags – A Sustainable Choice from a Trusted Manufacturer

As environmental awareness grows, both consumers and businesses are seeking packaging solutions that combine functionality with sustainability. One of the most effective ways to reduce plastic waste is by using recycled plastic bags. At Uniplast Bajer sp.j., we have years of experience in producing durable plastic packaging made from recycled LDPE and HDPE, helping our clients make more environmentally responsible choices. ... »

Plastics - Environmental Enemy or Eco Ally?

Plastics are both essential and controversial. For decades, they symbolized innovation and convenience – but now they’re often seen as an environmental threat. Is that fair? In this article, we explain why LDPE and HDPE films made from recycled material remain one of the most efficient and eco-friendly packaging options available. See how Uniplast, a trusted plastic bag manufacturer, combines practicality with responsibility. ... »

Why does embossing a plastic bag matter?

At Uniplast Bajer, we know that a good plastic bag isn’t just strong – it should also be comfortable to use. That’s why many of our HDPE and LDPE bags feature embossed surfaces. - Better grip – easier to open and carry, even with gloves - Faster packing – no struggling with slippery film - Clean look – hides minor imperfections, especially in recycled film - Added strength – embossed areas resist tearing A small technical detail – but a big difference in daily use. We manufacture HDPE and LDPE bags with embossing, printing, perforation – and from recycled material. #EmbossedBags #PlasticPackaging #LDPEbags #HDPEbags #RecycledPlastic #Uniplast #PlasticBagManufacturer #IndustrialPackaging #FlexiblePackaging #GripMatters ... »

Do plastic packaging bans help the planet – or just create confusion?

New regulations are targeting plastic packaging, even when it’s more hygienic and environmentally friendly than paper alternatives. Bans on HDPE and LDPE film for “on-site” meals promote solutions that are heavier, less recyclable, and less sustainable. In this article, as a manufacturer of recycled plastic bags and films, we explain why well-designed plastic packaging still makes sense – especially in the food and industrial sectors. ... »

Printing on Plastic Bags – What You Should Know Before Placing an Order

Planning to order plastic bags with your logo? Before submitting your artwork, learn how flexographic printing works, what types of film are suitable, what inks we use, and how we ensure print durability. At Uniplast, we specialize in inline flexo printing – continuous or registered – with reliable quality and resistance. Discover the full process from design to finished product. ... »

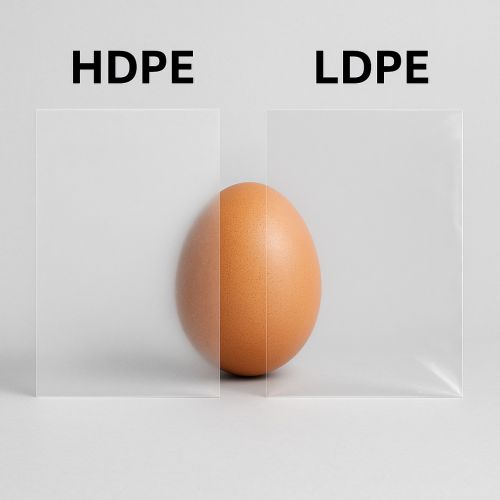

Transparency of HDPE and LDPE Films – Differences, Applications, Practical Tips

HDPE and LDPE Film Transparency – Differences You Can See Do HDPE and LDPE films look the same? Not at all. Although both materials are polyethylene, their transparency and appearance differ significantly. HDPE is matte and milky, while LDPE is more transparent – but never fully clear. In this article, we explain: - Why HDPE is more matte than LDPE, - What affects film transparency (thickness, additives, production), - When to choose HDPE film and when LDPE, - How transparency impacts the use of plastic bags and packaging. See a practical comparison and learn how to select the right film for your product. ... »

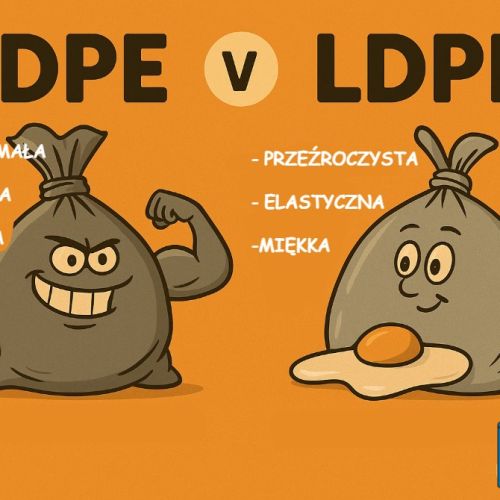

HDPE and LDPE Bags – Differences, Applications, Benefits I Uniplast

HDPE and LDPE Bags – Differences, Applications, Benefits | Uniplast HDPE and LDPE plastic bags are essential packaging materials in industry, trade, and logistics. Although they look similar, they differ in density, durability, and flexibility. This article explains when to choose HDPE, when LDPE, and what to consider when selecting plastic packaging. We also discuss how recycling-based production impacts both the environment and the economy. ... »

Plastic Pyrolysis – Potential, Limitations, and Role in Recovering Difficult Waste

Plastic pyrolysis is a chemical recycling technology gaining importance in the context of recycling challenging fractions: multilayered, contaminated, and unsortable. For companies producing plastic packaging, such as Uniplast – manufacturer of HDPE and LDPE plastic bags, understanding the possibilities of pyrolysis is strategically significant. This process allows partial closure of the material loop where mechanical recycling becomes inefficient. ... »

Which Plastics Are Truly Worth Recovering - from the Perspective of Practice, Market, and Science?

As both a manufacturer and a long-time professional in the plastics industry, I increasingly observe that the topic of recycling clashes with technical, market, and legislative realities. Public discourse often assumes that almost every plastic can and should be recycled. However, daily practice shows that not everything can be recovered in a meaningful way—technologically and economically. In this article—the first in the series “Plastics in the Fire of Decision”—I share my observations, supported by reliable sources and data. I will discuss which materials currently have real value in recycling, which remain problematic, and which might be better approached differently than before. I do not judge or moralize—but seek an honest answer to the question: what can truly be returned to the cycle, and what are we merely pretending to recover? ... »

PPWR – What does the new EU packaging regulation mean for plastic bag producers?

New EU Packaging Regulations (PPWR) – What Do They Mean for Plastic Bag Manufacturers? In 2025, the European Union's Regulation (EU) 2025/40 on packaging and packaging waste (PPWR) will come into effect. What challenges does this pose for plastic packaging producers? At Uniplast, we are proactively adapting our processes, focusing on internal recycling and eco-design.RIGK HOME+2ePac Flexible Packaging+2Source Green+2 Learn more about PPWR and our approach. #PlasticBags #LDPE #HDPE #PPWR #SustainablePackaging #Recycling #Regranulate #PackagingCompliance #CircularEconomy #Uniplast #EcoDesign #PackagingInnovation #RecyclableFilm #FilmProduction #PlasticProcessing #Packaging2025 ... »

Plastics and the Environment – Is the Material the Problem or How We Manage It?

Is plastic the real environmental threat, or is the issue how we manage it? Discover how Uniplast combines modern plastic bag manufacturing with responsible material use and in-house recycling. ... »

Stability of the HDPE/LDPE Film Extrusion Process – Key Challenges and Solutions

Adding LDPE regranulate to HDPE film production offers economic and environmental benefits, but also technological challenges, such as bubble instability, pressure fluctuations, surface defects, and irregular film thickness. What are the main causes of these issues? Which technological solutions can ensure process stability and consistent film quality? ... »

How to Optimize the Extrusion Parameters for HDPE/LDPE Film with Regranulate?

Extruding HDPE/LDPE film with regranulate requires precise process adjustments to maintain stable production and high-quality film. Optimizing temperature, MFI, screw speed, and Blow-Up Ratio (BUR) prevents melt flow issues and ensures consistent mechanical properties. What are the best settings for different LDPE/HDPE ratios? How can process control allow for higher regranulate content without compromising film performance? ... »

.webp)

How Does LDPE Regranulate Affect the Mechanical Properties of HDPE Film?

Using LDPE regranulate in HDPE film production helps reduce raw material costs and promotes sustainability. However, blending these two materials significantly impacts tensile strength, flexibility, puncture resistance, and hardness. Does a higher LDPE content always weaken the film? How can you optimize the HDPE/LDPE ratio to maintain high product quality? In our article, we analyze the impact of LDPE on film properties and provide key insights on process control. ... »

The Role of Internal Recycling in Sustainable LDPE and HDPE Film Production

With increasing environmental requirements and the need for efficient resource management, internal recycling plays a key role in LDPE and HDPE film production. This process involves recovering and reusing defective film products that do not meet quality standards. By using regranulation technology, these materials are converted into high-quality raw material, reducing the need for virgin plastics and lowering the carbon footprint. Implementing internal recycling is a step toward sustainable development and more efficient waste management in the plastics industry. ... »